Welcome to the Safe Sodium Hydroxide Handling Guide. In this guide, I will provide you with essential information on how to safely use and handle sodium hydroxide, also known as caustic soda or lye. Sodium hydroxide is a highly caustic base and alkali that requires proper safety precautions and awareness of its potential hazards. Whether you are using it in soap making or any other application, it is crucial to prioritize safety.

Sodium hydroxide has a wide range of uses and applications across various industries. Understanding its properties, proper handling procedures, and necessary safety measures is essential to ensure your well-being and the safety of those around you. From its production to storage and disposal, we will cover all the important aspects of sodium hydroxide handling in this guide.

Key Takeaways:

- Proper safety training and awareness are vital when working with sodium hydroxide.

- Sodium hydroxide is used in various industries and applications.

- Always follow safety precautions, wear appropriate personal protective equipment (PPE), and store sodium hydroxide correctly.

- In case of exposure or emergencies, take immediate first aid measures and seek medical attention.

- Proper storage, disposal, and spill response are crucial to minimize risks associated with sodium hydroxide.

About Sodium Hydroxide

Sodium Hydroxide, also known as caustic soda or lye, is a highly corrosive and strong base. It is commonly made through the electrolysis of brine in a process known as the Chlor-alkali process. Depending on the grade, Sodium Hydroxide may appear clear or slightly cloudy.

With its versatile properties, Sodium Hydroxide finds application in various industries. It is used in the production of pulp and paper, where it assists in breaking down the raw material. Additionally, it plays a crucial role in water treatment processes, helping to regulate pH levels and remove impurities. Sodium Hydroxide is even utilized in food preparation, best known for giving pretzels their crispy crust.

When it comes to industrial applications, Sodium Hydroxide proves its worth. It is employed in roadkill digestion, aiding in the safe disposal of animal remains. Its ability to dissolve grease and fats makes it a key ingredient in drain cleaners.

Understanding the wide range of uses and applications of Sodium Hydroxide is essential for those who handle this potentially hazardous chemical.

| Industry | Application |

|---|---|

| Pulp and paper | Breaking down raw materials |

| Water treatment | pH regulation, impurity removal |

| Food preparation | Crusty texture in baked goods |

| Industrial | Roadkill digestion, drain cleaners |

Hazard Statements and Safety Measures

In the Safe Sodium Hydroxide Handling Guide, it is crucial to understand the hazards associated with sodium hydroxide and take necessary safety precautions. Sodium hydroxide is a highly corrosive substance that can cause severe burns and eye damage if not handled properly. It is essential to store sodium hydroxide in a corrosive-resistant container, tightly closed, and in a cool, dry, and well-ventilated place to minimize the risk of accidents and exposure.

When working with sodium hydroxide, it is important to wear appropriate personal protective equipment (PPE) to ensure safety. This includes chemical splash goggles, a face shield, a chemical-resistant suit and rubber boots, and chemical-resistant gloves to protect against potential contact with the substance.

“Sodium hydroxide is corrosive to metals and can cause severe burns and eye damage.”

In case of exposure to sodium hydroxide, immediate action should be taken. If there is contact with the skin or eyes, it is crucial to rinse the affected area with water for at least 15 minutes. Seeking medical attention is also important to ensure proper treatment and care. First aid measures should be followed to reduce the harmful effects of sodium hydroxide on the body.

Key Safety Measures for Sodium Hydroxide:

- Store sodium hydroxide in a corrosive-resistant container, tightly closed, and in a cool, dry, and well-ventilated place.

- Wear personal protective equipment (PPE) including chemical splash goggles, a face shield, a chemical-resistant suit and rubber boots, and chemical-resistant gloves when handling sodium hydroxide.

- In case of exposure, rinse affected areas with water for at least 15 minutes and seek immediate medical attention.

Sodium Hydroxide Storage and Disposal

Proper storage and disposal of sodium hydroxide are essential to maintain safety and minimize potential risks. Follow these guidelines to ensure the safe handling and management of sodium hydroxide.

Sodium Hydroxide Storage

When storing sodium hydroxide, it is crucial to adhere to specific precautions to prevent accidents and maintain the integrity of the chemical:

- Store sodium hydroxide in its original container, tightly closed, and locked up.

- Use a corrosive-resistant container with a resistant inner liner to store sodium hydroxide.

- Keep the storage area cool, dry, and well-ventilated.

By following these storage practices, you can minimize the risks associated with sodium hydroxide and ensure its stability over time.

Sodium Hydroxide Disposal

Proper disposal of sodium hydroxide is essential to protect the environment and comply with regulations. Disposal methods may vary depending on local, regional, national, and international regulations. It is important to:

- Dispose of sodium hydroxide according to applicable regulations.

- Ensure proper handling procedures to minimize heat generation and avoid contact with water during disposal.

Consult local authorities or waste management professionals to determine the appropriate disposal method in your area.

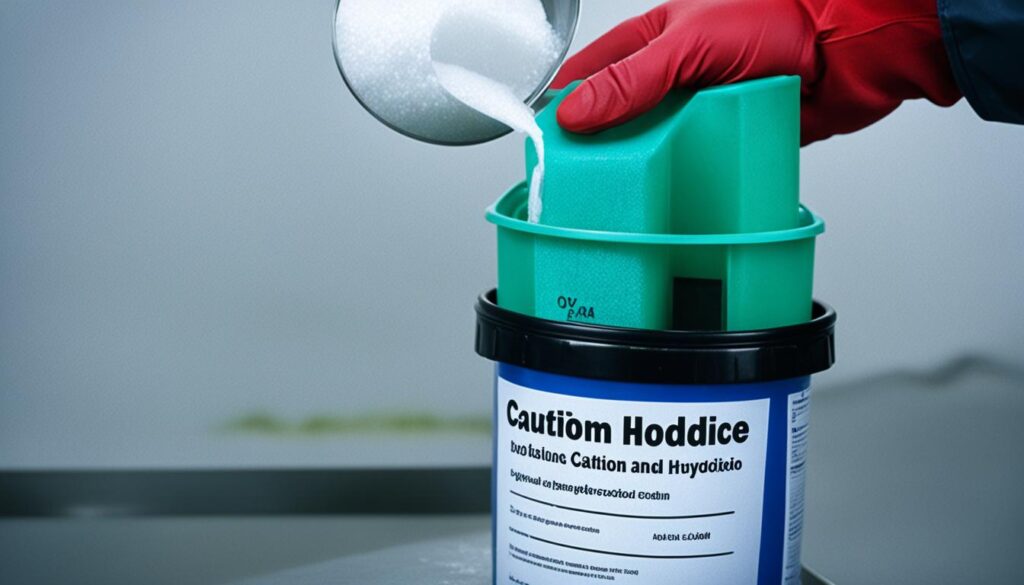

Image: Sodium Hydroxide Storage

Table: Sodium Hydroxide Storage and Disposal Summary

| Storage | Disposal |

|---|---|

| Store in original, tightly closed, and locked container | Dispose according to applicable regulations |

| Use a corrosive-resistant container with a resistant inner liner | Follow proper handling procedures to minimize heat generation and avoid contact with water |

| Keep storage area cool, dry, and well-ventilated | Consult local authorities or waste management professionals |

In this section, we have discussed the importance of proper storage and disposal of sodium hydroxide. By following the guidelines provided, you can ensure the safe handling and management of this chemical, minimizing the risks associated with it. The image above illustrates the proper storage of sodium hydroxide, while the table summarizes the key points for storage and disposal. It is crucial to comply with regulations and consult with local authorities for appropriate disposal methods in your area.

Personal Protective Equipment (PPE)

When working with Sodium Hydroxide, it is crucial to prioritize safety by wearing the appropriate personal protective equipment (PPE). This will help protect against potential hazards and minimize the risk of accidents. Here are the essential PPE items to consider:

- Chemical splash goggles: These close-fitting goggles provide eye protection from chemical splashes and prevent direct contact with Sodium Hydroxide.

- Face shield: A face shield offers additional protection for the face and neck areas, shielding against potential splashes and spills.

- Chemical-resistant suit and rubber boots: Wearing a chemical-resistant suit and rubber boots helps safeguard the body and feet against direct contact with the caustic properties of Sodium Hydroxide.

- Chemical-resistant gloves: Gloves made from chemical-resistant materials, such as neoprene or nitrile, create a barrier between the skin and Sodium Hydroxide, reducing the risk of chemical burns or irritation.

In certain situations where exposure to Sodium Hydroxide may exceed regulatory limits, respiratory protection, such as a properly fitted mask or respirator, should be worn. Additionally, it is essential to observe good personal hygiene practices, including washing hands thoroughly with soap and water after handling the chemical, and before eating, drinking, or smoking.

Remember, proper usage of PPE is vital in preventing accidents and ensuring personal safety when handling Sodium Hydroxide.

Emergency Response

In case of emergencies involving Sodium Hydroxide, it is crucial to take specific first aid measures to ensure the safety of individuals. Remember that prompt action can make a significant difference in mitigating the potential harm caused by sodium hydroxide exposure.

If sodium hydroxide is swallowed, it is recommended to rinse the mouth with water and drink plenty of water. However, it is important not to induce vomiting, as this can further aggravate the situation.

In the event of inhalation, it is essential to move to an area with fresh air immediately. If necessary, provide artificial respiration to aid breathing. Seek medical attention promptly to assess the severity of the exposure.

For skin contact, it is crucial to remove contaminated clothing and rinse the affected area with ample amounts of water. This action helps to minimize further absorption of the chemical into the skin.

In case of eye contact, it is of utmost importance to flush the eyes with water continuously for at least 15 minutes. This will help to dilute and remove the sodium hydroxide from the eyes. It is paramount to seek immediate medical attention to ensure proper treatment and prevent any potential complications.

Remember, in any emergency involving sodium hydroxide, seeking medical attention should always be a priority. Contact a poison center or doctor to receive professional guidance and assistance.

Sodium Hydroxide Spill Reporting and Neutralization

In the event of a Sodium Hydroxide spill, immediate action is crucial to minimize potential damage and ensure the safety of individuals and the environment. Here are the necessary steps to handle a Sodium Hydroxide spill:

1. Contain and Collect the Spill

First and foremost, you should isolate the spill area to prevent further spread. Use suitable materials such as absorbents or neutralizers to contain the spill and prevent it from seeping into drains or other sensitive areas.

2. Neutralize the Residue

Sodium Hydroxide, being a strong base, requires neutralization to render it safe. A dilute or weak acid can be used to neutralize the residue. Care should be taken to choose an appropriate acid that is compatible with Sodium Hydroxide. Follow the safety guidelines and use protective equipment while neutralizing the spill.

3. Flush the Spill Area with Water

After neutralizing the spill, thoroughly flush the spill area with water to dilute any remaining Sodium Hydroxide and remove any traces. This step helps ensure that the area is safe and free from any residual hazards.

4. Notify the Applicable Government Authority

If the Sodium Hydroxide spill is significant, reportable, or has the potential to harm the environment, it is important to notify the appropriate government authority. They can provide further guidance on containment measures, cleanup procedures, and any necessary environmental assessment.

By following these spill reporting and neutralization protocols, you can effectively mitigate the risks associated with Sodium Hydroxide spills and contribute to a safer working environment.

Stability, Reactivity, and Fire Hazards

When handling and storing sodium hydroxide, it is crucial to be aware of its stability, reactivity, and fire hazards. Sodium hydroxide is typically stable, but it can react violently with water and is incompatible with many common chemicals. The chemical reaction between sodium hydroxide and metals can generate highly flammable hydrogen gas.

In order to mitigate these hazards, it is important to handle and store sodium hydroxide away from moisture or humidity. Additionally, it is essential to avoid generating dusts, as they can become flammable and pose a fire risk.

In case of a fire involving sodium hydroxide, it is important to use suitable extinguishing media that are compatible with the chemical. Precautions should be taken to prevent pressure buildup and the generation of toxic fumes.

Proper safety measures must be in place to minimize the risk of fire and ensure the safe handling of sodium hydroxide.

Engineering Controls and Storage Practices

When it comes to sodium hydroxide production and handling, implementing proper engineering controls and storage practices is crucial. These measures ensure the safe containment and utilization of this highly caustic substance.

Local Exhaust Ventilation

One effective engineering control method is the use of local exhaust ventilation. By installing ventilation systems near areas where sodium hydroxide is handled or produced, the release of the chemical into the air can be minimized. This helps to maintain a safer environment for workers and reduces the risk of inhalation or exposure.

Enclosures

In addition to local exhaust ventilation, enclosures can be used to further control the amount of sodium hydroxide in the air. These enclosures provide an additional barrier between workers and the chemical, preventing direct contact and reducing the chances of accidental exposure.

Storage Area Requirements

Proper storage practices are essential for sodium hydroxide handling. Storage areas should be cool, dry, and well-ventilated to maintain the integrity of the chemical and prevent degradation. It is crucial to keep sodium hydroxide containers separate from incompatible materials to avoid any potential reactions or hazards.

Corrosion-Resistant Tools and Equipment

When working with sodium hydroxide, it is important to use corrosion-resistant tools and equipment. This ensures that the containers and instruments used for handling and production can withstand the corrosive nature of the chemical, reducing the risk of leaks, spills, or other accidents.

Proper Container Handling and Closure

Containers holding sodium hydroxide should always be handled with care and kept tightly closed when not in use. Empty containers should not be reused, as they may still contain residue or pose a risk of contamination. Following proper handling and closure practices helps maintain the quality and safety of the chemical.

Incorporating these engineering controls and storage practices is essential for a safe sodium hydroxide production and handling environment. By implementing these measures, industries can minimize the risk of accidents, protect the health and safety of workers, and maintain the integrity of this powerful chemical compound.

Exposure Limits and Personal Protective Equipment

When working with Sodium Hydroxide, it is crucial to understand the exposure limits set by industry experts. The American Conference of Governmental Industrial Hygienists (ACGIH®) recommends a threshold limit value of 2 mg/m3 (C) for Sodium Hydroxide. This limit helps to ensure worker safety and minimize the risk of harmful exposure.

To protect yourself and prevent any potential hazards, it is essential to use appropriate personal protective equipment (PPE) when handling Sodium Hydroxide. The recommended PPE includes:

- Chemical safety goggles: These protect your eyes from splashes and spills that could cause severe eye damage.

- Impervious gloves: Use gloves made from chemical-resistant materials to shield your hands from direct contact with Sodium Hydroxide.

- Appropriate respiratory protection: Depending on the concentration and duration of exposure, respiratory protection may be necessary. Consult relevant safety guidelines and regulations to determine the type of respiratory protection required.

By wearing the correct PPE, you can significantly reduce the risk of skin and eye contact, inhalation, and other potential hazards associated with Sodium Hydroxide handling.

Remember:

Always prioritize your safety by following established guidelines and using the proper protective equipment when working with Sodium Hydroxide.

Unintentional Release Measures

In the rare event of an unintentional release of Sodium Hydroxide, it is crucial to prioritize personal safety by immediately evacuating and isolating the affected area. By taking these precautions, we ensure the protection of both individuals and the surrounding environment.

Once personal safety has been addressed, it is important to contain and clean up the spill promptly and effectively. Utilize absorbents that do not react with Sodium Hydroxide to minimize the chemical’s spread and potential hazards. Thoroughly and carefully dispose of the absorbed material according to proper protocols and regulations to prevent any further contamination or risks.

Remember, prompt action and adherence to appropriate safety measures are essential in dealing with unintended releases of Sodium Hydroxide. By following these guidelines, we can minimize potential damage and safeguard both people and the environment.

FAQ

How can sodium hydroxide be used?

Sodium hydroxide is used in various industries such as pulp and paper, water treatment, pH regulation, and even in food preparation. Its uses range from giving pretzels their crispy crust to industrial applications like roadkill digestion.

What are the safety precautions for handling sodium hydroxide?

When handling sodium hydroxide, it is important to wear personal protective equipment (PPE) such as chemical splash goggles, a face shield, a chemical-resistant suit and rubber boots, and chemical-resistant gloves. Good personal hygiene measures should also be observed, such as washing after handling the chemical and before eating, drinking, or smoking.

What should I do in case of exposure to sodium hydroxide?

In case of exposure, specific first aid measures should be taken, such as rinsing with water or seeking medical attention. If swallowed, rinsing the mouth and drinking plenty of water is recommended, but vomiting should not be induced. Inhalation requires moving to fresh air and, if necessary, providing artificial respiration. Skin contact should be immediately treated by removing contaminated clothing and washing the affected area with plenty of water. In case of eye contact, flushing with water for at least 15 minutes is necessary. It is important to seek medical attention immediately and call a poison center or doctor.

How should sodium hydroxide spills be handled?

In the event of a sodium hydroxide spill, it is important to contain and collect the spill and neutralize the residue with a dilute or weak acid. Spill areas should be flushed with water, and the applicable government authority should be notified if the spill is reportable or could harm the environment.

What are the stability and reactivity hazards associated with sodium hydroxide?

Sodium hydroxide is normally stable, but it reacts violently with water and is incompatible with many common chemicals. It can generate highly flammable hydrogen gas when in contact with metals. It is important to handle and store sodium hydroxide away from moisture or humidity and avoid generating dusts. In case of fire, suitable extinguishing media should be used, and precautions should be taken to prevent pressure buildup and toxic fume generation.

What are the engineering controls and storage practices for sodium hydroxide?

Engineering controls, such as local exhaust ventilation and enclosures, should be used to control the amount of sodium hydroxide in the air. Storage areas should be cool, dry, well-ventilated, and separate from incompatible materials. Corrosion-resistant tools and equipment should be used, and empty containers should not be reused. It is important to keep containers tightly closed and follow proper handling and storage practices.

What are the exposure limits and personal protective equipment recommendations for sodium hydroxide?

The American Conference of Governmental Industrial Hygienists (ACGIH®) recommends a threshold limit value of 2 mg/m3 (C) for Sodium Hydroxide. Personal protective equipment (PPE) such as chemical safety goggles, impervious gloves, and appropriate respiratory protection should be used when working with sodium hydroxide.

What should I do in case of an unintentional release of sodium hydroxide?

In the event of an unintentional release of sodium hydroxide, personal precautions such as evacuation and isolation of the area should be taken. Containment and cleanup should be done using absorbents that do not react with the chemical, and proper disposal methods should be followed.